Business

/ArcaMax

Lawsuit alleges Google chatbot was behind a user's delusions and death

Google's artificial intelligence chatbot Gemini encouraged a 36-year-old Florida man to embark on violent missions and to take his own life, a lawsuit alleges.

The man, Jonathan Gavalas, started using the chatbot in August 2025 to help write, plan travel and assist with shopping. But after he activated Google's most intelligent AI model, Gemini...Read more

As gas prices rise, California gets punched harder at the pump than other states

Californians are feeling more pain at the pump than any other state as the conflict with Iran pushes up prices.

Spencer Shearer was filling up his Nissan Sentra on Friday morning at the Chevron station in Brentwood near San Vicente and Montana avenues and paying a rate higher than almost anywhere else in the country: $5.55 per gallon.

"It ...Read more

Judge sends former Google chief's spying, sexual assault lawsuit to arbitration

A lawsuit filed by a former girlfriend and business partner of tech billionaire Eric Schmidt accusing him of sexual assault was sent to arbitration this week by a Los Angeles judge.

Michelle Ritter, 32, of Los Angeles, alleged that a 2022 federal law inspired by the #MeToo movement intended to end forced arbitration of sexual assault and ...Read more

Labubu maker Pop Mart is opening US headquarters in Culver City

Pop Mart, the Chinese toymaker known for its collectible Labubu dolls, reportedly plans to open a new office building in Culver City as it seeks to expand its North American presence.

The 22,000-square-foot office will serve as Pop Mart's new U.S. headquarters, according to real estate data provider CoStar, which earlier reported the deal.

Pop...Read more

Mercedes-Benz settles case over alleged union-busting in Alabama

Mercedes-Benz Group AG vowed not to make anti-union threats as part of a deal to resolve a U.S. labor board case over the company’s response to a high-stakes Alabama organizing drive.Under a settlement with the National Labor Relations Board, the automaker said it will distribute, and adhere to, a notice about employees’ union organizing ...Read more

Michigan regulators tell marijuana shops to stop using dispensary label

LANSING, Michigan — The state's marijuana regulator is instructing marijuana retail shops and provisioning centers to stop referring to themselves as dispensaries, stressing that the term, legally, is reserved for pharmacies.

The reminder issued to licensed cannabis retailers on Wednesday was first issued in a 2019 bulletin, but was repeated ...Read more

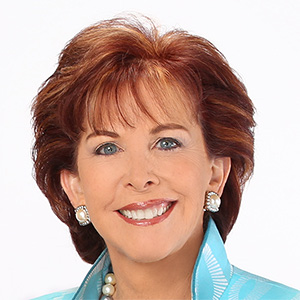

Terry Savage: Social Security Fairness Act windfalls can surprise some seniors with higher property tax bill

Seniors who received a windfall deposit as a result of the Social Security Fairness Act are now finding that the consequences of that unexpected benefit can be costly, especially in Illinois.

As a reminder, early last year seniors who had been receiving reduced Social Security benefits because they also had public pension benefits suddenly ...Read more

Shock drop in US payrolls casts doubt on steadying job market

U.S. employers unexpectedly cut jobs in February and the unemployment rate rose, pointing to lingering fragility in a labor market that was thought to be stabilizing.

Nonfarm payrolls fell 92,000 last month, one of the largest declines since the pandemic, after a strong start to the year. While some of the downside was expected in advance, like...Read more

Rocket accused of kickback scheme, hiking cost of homebuying

A lawsuit alleging hundreds of thousands of homebuyers overpaid because Detroit-based Rocket Companies' mortgage unit colluded with real estate agents highlights decades-old affordable housing issues and the role of federal watchdogs under President Donald Trump.

Plaintiffs' attorneys in a January lawsuit describe the alleged deal between ...Read more

The secret vehicle Ford built that CEO Farley just gave to Pope Leo

Ford Motor Co.'s CEO and his wife have donated to Pope Leo XIV a secretly built, customized 2026 Ford Explorer hybrid SUV built in the pope's native Chicago.

Jim and Lia Farley gifted the vehicle in the presence of the Pontiff during a ceremony that took place on Feb. 28, marking the first time a Ford CEO has had an audience with the pope at ...Read more

Michael Hiltzik: In two new court cases, judges find that AI does not have human intelligence

It's becoming clearer with every passing day that the only people making a serious effort to come to grips with the implications of artificial intelligence for society aren't legislators, or business leaders, or AI promoters themselves. They're judges.

Indeed, in recent weeks, judges in two federal cases have drawn a line that seems to have ...Read more

Hundreds of applications, no jobs and AI replacements: California's brutal tech work landscape

Laid-off tech worker Joseph Tinner has spent almost a year hunting for a job. It has been a depressing crash course on the sea change in Silicon Valley.

The former product instructor from the San Francisco Bay Area has ridden the tech wave throughout his career, easily jumping from Verizon to Fitbit to Workday. Since losing his job early last ...Read more

How a successful Colorado startup turned into a nearly $1 billion health care fraud scheme

Marian Houk was rehabbing from a major spinal surgery in 2022 when her physical therapist at UCHealth in Aurora, Colorado, recommended she try electrical stimulation to manage the pain.

Like many providers around the country, UCHealth sent Houk to Zynex Inc., an Englewood, Colorado-based medical device company that manufactures and sells ...Read more

How our AI bots are ignoring their programming and giving hackers superpowers

Welcome to the age of AI hacking, in which the right prompts make amateurs into master hackers.

A group of cybercriminals recently used off-the-shelf artificial intelligence chatbots to steal data on nearly 200 million taxpayers. The bots provided the code and ready-to-execute plans to bypass firewalls.

Although they were explicitly programmed...Read more

Auto review: Subaru Trailseeker is an eOutback

LAGUNA BEACH, California — The Subaru Outback SUV is an icon. Now it has an electric sibling.

While the 2026 Outback has zigged to a square, truck-like ute design, the 2026 Trailseeker has zagged to Outback’s traditional wagon wardrobe with a side of off-road cladding and an infusion of high tech. I slipped into the driver seat, toggled the...Read more

Henry Payne: Ford kit boosts horsepower for F-150, Mustang V-8s

Ford Motor Co. is supercharging its F-150 and Mustang offerings for customers.

The Blue Oval joined the aftermarket horsepower wars this week by offering a factory-installed Whipple Supercharger Kit for purchase with a new pickup or muscle car.

That means a whopping power boost for the F-150’s 5.0-liter Coyote V-8 engine from 400 horsepower ...Read more

Auto review: 2026 Toyota Tundra delivers usage and comfort

The days of trucks being designed specifically for work and off-road use are virtually gone, as the truck market has shifted toward comfort and family-friendly vehicles fit for everyday driving.

As a full-four door with a CrewMax cab, the 2026 Toyota Tundra is a space machine that delivers storage and utility to consumers. Its ability to move ...Read more

Auto review: 2026 Mazda CX-5 gains a great new screen but loses something in the process

When was it decided that buttons in a car were old-fashioned? Surely it was some young punk designer in a black turtleneck who made the call. So, he took them out. All of them. And stuffed everything onto a screen the size of a small television. Naturally, the accountants applauded. No buttons to manufacture? This saves money. High fives all ...Read more

Federal court upholds Seattle's delivery driver rights law

Seattle’s law regulating when delivery drivers may be deactivated from platforms such as Uber and Instacart will remain in place after the Ninth Circuit Court of Appeals rejected the companies’ assertions it infringed on their First Amendment rights and was overly vague.

The split ruling from the three-judge panel likely means the law is ...Read more

Iran conflict sends farmers rushing to secure critical fertilizers

Chet Edinger had already bought most of the fertilizer for his corn and soybean farm last year, but on Monday morning, with war breaking out in the Middle East, he rushed to secure a last few truckloads of urea for the tens of thousands of acres he cultivates near Mitchell, South Dakota.

“We grabbed what we needed,” he said by phone. It ...Read more

Popular Stories

- Lawsuit alleges Google chatbot was behind a user's delusions and death

- As gas prices rise, California gets punched harder at the pump than other states

- Judge sends former Google chief's spying, sexual assault lawsuit to arbitration

- Labubu maker Pop Mart is opening US headquarters in Culver City

- Michigan regulators tell marijuana shops to stop using dispensary label